What is SLS Printing?

Technical Specifications

What is FDM Technology?

Selective Laser Sintering (SLS) is an industrial 3D printing process that uses a laser to fuse powdered nylon into strong, functional parts, layer by layer. It requires no support structures, enabling complex geometries and interlocking designs. SLS is ideal for durable prototypes, end-use parts, and low-volume production with excellent mechanical performance.

Explore Our SLS 3D Printing Services

Our SLS 3D printing offers durable, high-performance parts with complex geometries and no need for supports. Ideal for functional prototypes and small-batch production, we deliver strong, precise results with expert support from start to finish.

Specifications

Build Volume:

Layer Height:

Supported Materials:

Colors Available:

Lead Time:

Details

Up to 165 × 165 × 300 mm

110 micron

Nylon 12

Grey

From 7–14 working days, depending on quantity and size

Specifications

Build Volume: Up to 165 × 165 × 300 mm

Layer Height: 110 micron

Supported Materials: Nylon 12

Colors Available: Grey

Lead Time: From 7–14 working days, depending on quantity and size

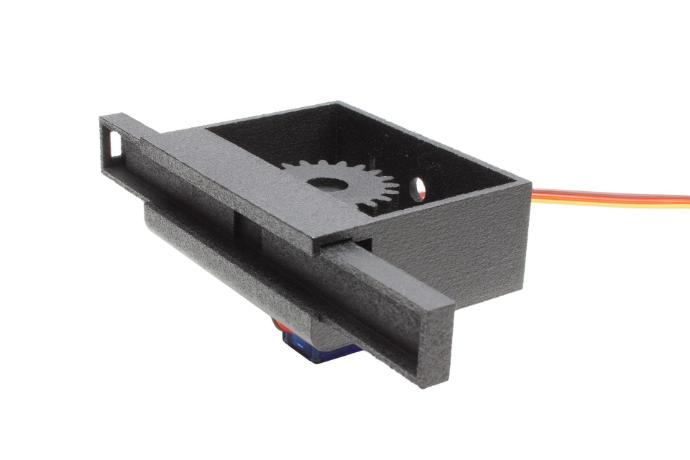

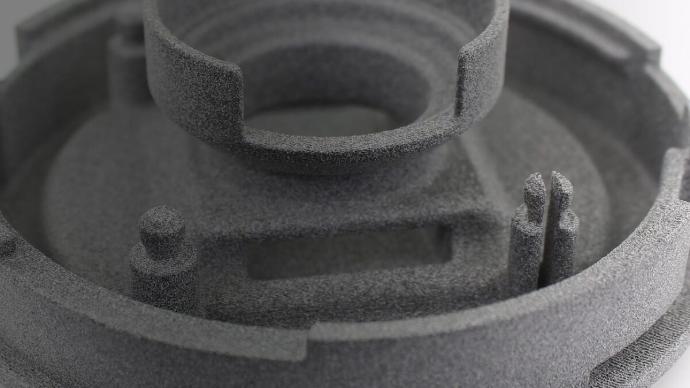

Complex Designs, Efficient Production

With SLS technology, you can create complex parts featuring internal channels, lattice structures, and nested assemblies—all without the need for support structures. This design freedom enables shapes that traditional manufacturing methods can’t achieve. Additionally, high packing density allows us to fit multiple parts into a single build, making batch production more efficient by lowering costs and speeding up delivery times.

Nylon 12

Nylon 12 (PA12) powder is a popular SLS material known for its strong, flexible, and durable parts. It produces accurate, functional components with a matte finish and no need for supports.

Parts printed with Nylon 12 offer excellent mechanical strength, chemical resistance, and low moisture absorption. Ideal for prototypes, complex assemblies, and low-volume production in industries like automotive, aerospace, and medical.

Example Prints