High Speed Compatible 300mm/s

High Speed Compatible 300mm/s

With high speed 3D printing becoming more prominent due to the introduction of high speed 3D printers, FormFutura is excited to introduce a range of new and existing upgraded materials to our assortment. These materials, while still suitable for traditional printers, have also been fully optimized for the new high speed 3D printing technology.

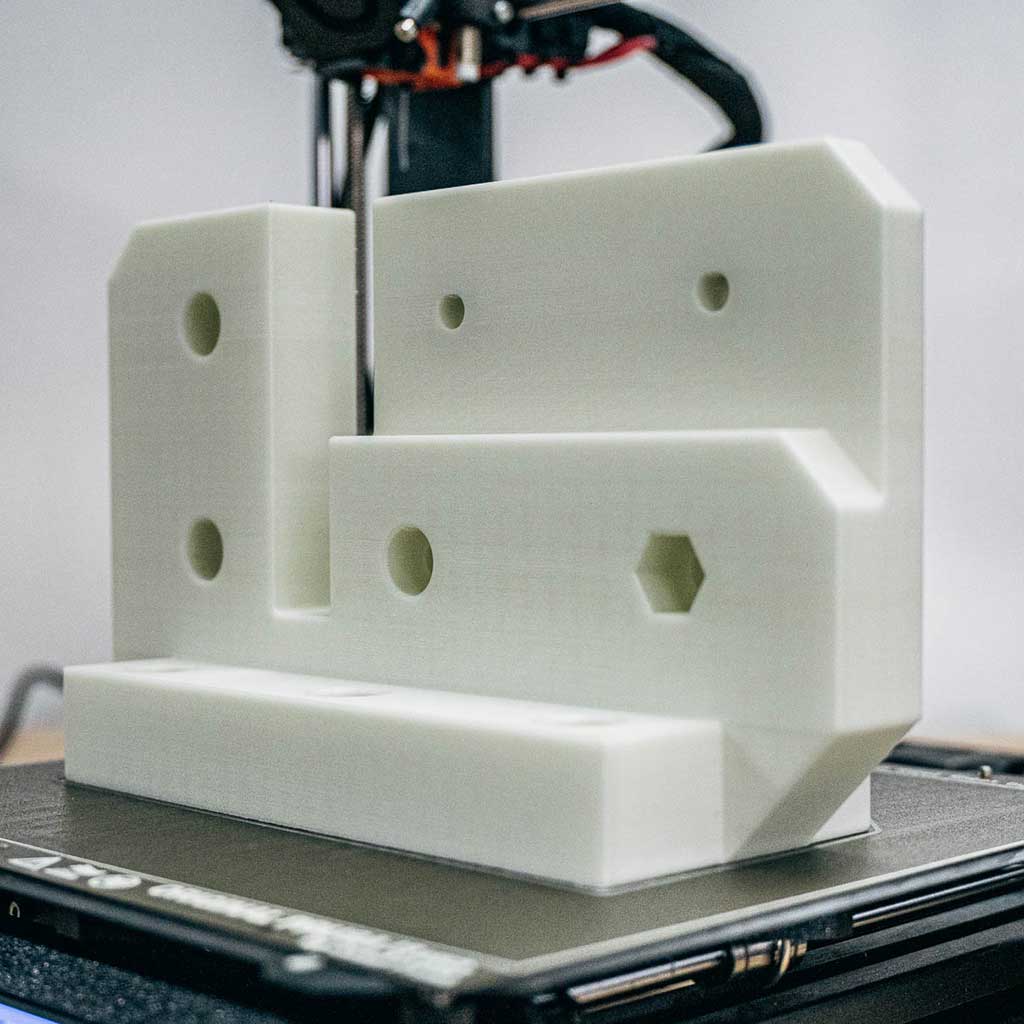

After annealing Volcano PLA is heat resistant up to 95° C. It is an industrial grade PLA filament engineered for high printing speeds. Its mechanical properties are similar to ABS but with the added benefit of being both biodegradable and easy to print. Volcano PLA has a high impact resistance and low shrinkage, making it the ideal PLA-based filament for industrial applications.

Unique features

- High heat resistance of ≥ 95° C after annealing

- Less than 0.3% shrinkage after annealing

- Roughly 8 times less shrinkage compared to competitor materials available on the market

- Engineered to have excellent dimensional accuracy before and after annealing

- Engineered for high printing speeds of > 120mm/s

- Highly crystalline immediately after extruding resulting in increased stiffness and temperature resistance

- Superb mechanical properties comparable to ABS

- Excellent interlayer adhesion

- Biodegradable

- Matte surface finish

General printing guidelines *

| Nozzle size: ≥ 0.15mm | Layer height: ≥ 0.06mm | Flow rate: ± 95 – 110% |

| Print temp: ± 230 – 265° C * | Print speed: High | Retraction: Yes ± 5mm |

| Heat bed: ± 0 – 60° C * | Fan speed: 50-100% | Experience level: Beginner |

*) Above displayed settings are meant as guidance to find your optimal print settings. These ranges in settings should work for most printers, but please do feel free to experiment outside these ranges if you think it is suitable for your printer. There are a lot of different type of printers, hot-ends and printer offsets that it is extremely difficult to give an overall one-size-fits-all setting.

*) Flow rate depends on printing speed and type of hotend used. For full metal hotends a lower flow rate is recommended and for high printing speeds a high(er) flow rate is recommended.

Annealing Volcano PLA

Annealing is a secondary process in which a plastic part is heated up to half of the melt temperature for a moderate period of time before letting the plastic part cool back down to room temperature. When the plastic part is reheated (annealed) like this, the material relaxes and internal stresses and/or strains are relieved resulting in improved dimensional stability, reduction/removal of dimensional distortion and defects, and improved physical and thermal properties of the printed (and annealed) plastic object.

*)When using high speed printing, the above displayed settings will likely need to be adjusted accordingly.

Step 1

Preheat a convection oven at 110° C (half the melting temperature of Volcano PLA). It is highly recommended to use a thermometer to calibrate the exact temperature of your convection oven.

Preheating the oven to 110° C is extremely important as your Volcano PLA printed object will then crystalize in such a rapid timeframe that there is almost no time for the material to shrink. This results in a negligible shrinkage percentage of < 0.3% and by that Volcano PLA is unsurpassed when it comes to reduction of shrinkage after annealing.

Step 2

When the oven is preheated to a stable temperature of 90° C then quickly put your Volcano PLA printed object in the oven. Make sure to do this as quick as possible in order to keep the loss of heat reduced to a minimum. Don’t remove any supports (if used) from the printed object when putting it in the oven.

It is recommended to place the Volcano PLA printed object on a flat aluminium sheet/foil or similar flat metal object to obtain a stable/equal heat transmission.

Small objects – 20 minutes timer

For small objects with thin walls and medium infill annealing will take ± 20 minutes

Large objects – 60 minutes timer

For large objects with thick walls and medium/high infill annealing take ± 60 minutes

Step 3

When the object is annealed taking above mentioned duration into account then switch off the oven and let it cool down to room temperature. Do not remove the object before the oven has completely cooled down to room temperature!

Step 4

When the oven is cooled down completely you remove the object from the oven and remove any support material (if used). Your Volcano PLA printed object is now annealed and has all thermal and mechanical properties as displayed in the Technical Data Sheet (TDS).

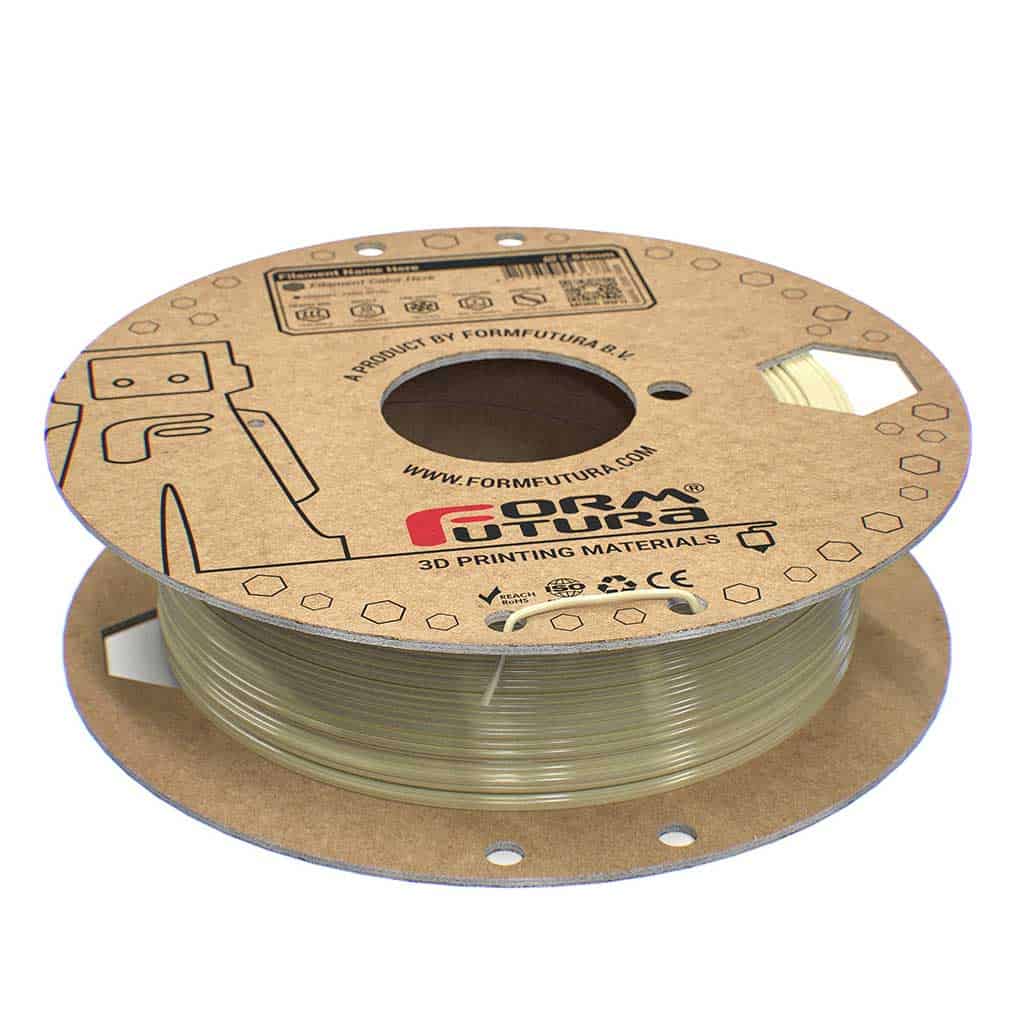

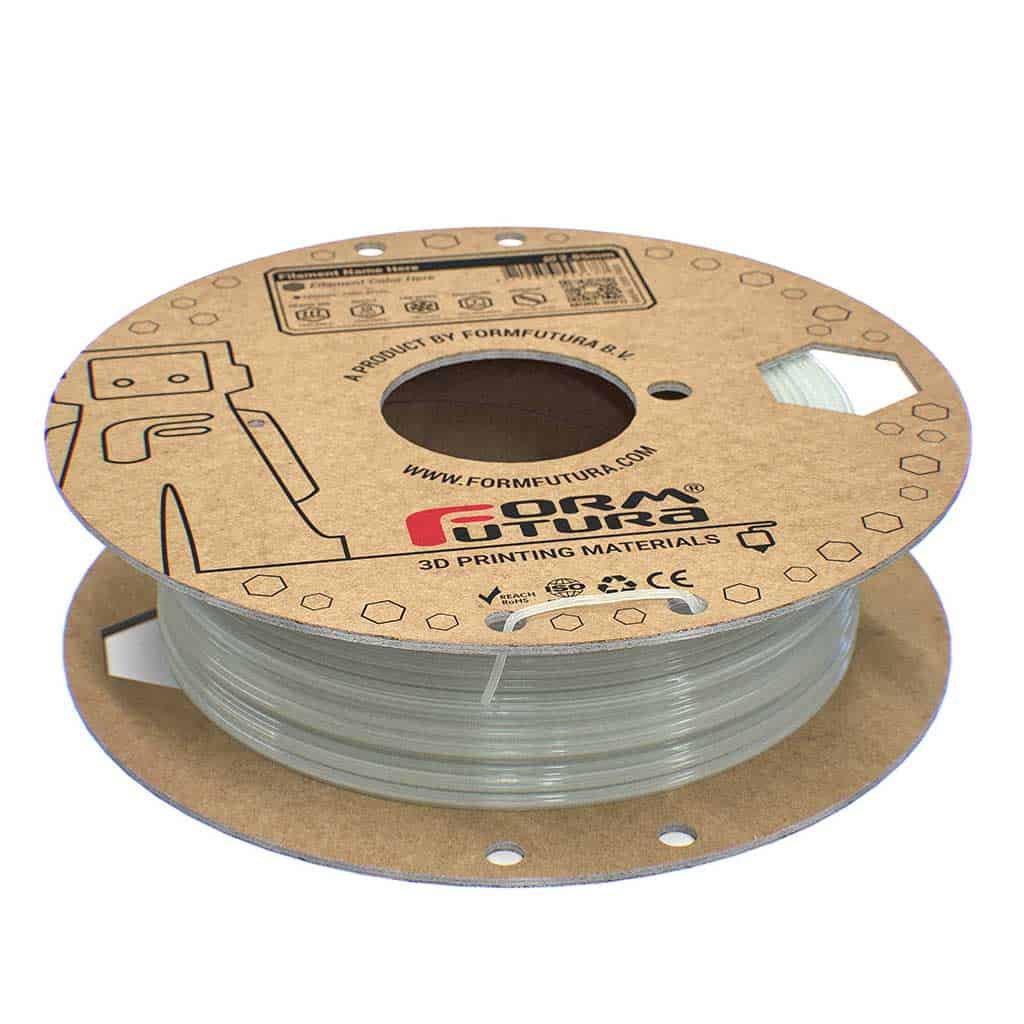

Filament length

| ρ: 1.27 g/cc | 50 gr coil | 0.5 Kg spool | 2.3 Kg spool | 4.5 Kg spool | 8 Kg spool |

| Ø 1.75mm | ± 16.4m | ± 246m | ± 753m | ± 1473m | ± 2619m |

| Ø 2.85mm | ± 6.2m | ± 93m | ± 284m | ± 555m | ± 987m |

Product export information

| HS Code: 39169090 | Description: Monofilament | Country of origin: the Netherlands |

Compliance *

This filament is compliant to below listed directives and regulations.

- RoHS directive 2011/65/EC

- REACH directive 1907/2006/EC

*) This declaration of conformity to directives and regulations is prepared according to our present standard of knowledge and may be amended if new cognitions are available and applies only for the above described products.

Safety Datasheet: