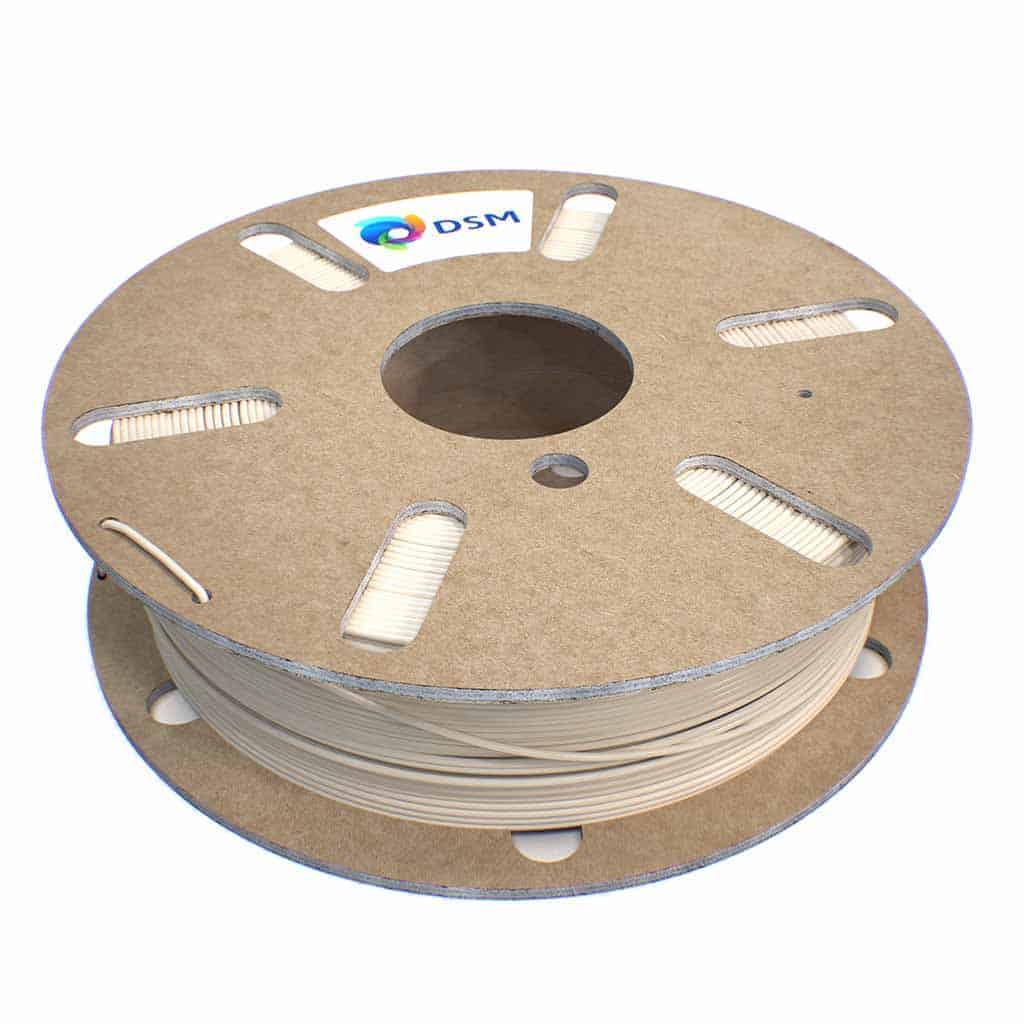

Addigy® F1030 FR is the replacement for Novamid® AM1030 FR filament. The product is the same, only the name has been changed.

Addigy® F1030 FR is the first-ever UL Blue Card certified PA6/66 3D printer filament for open systems.

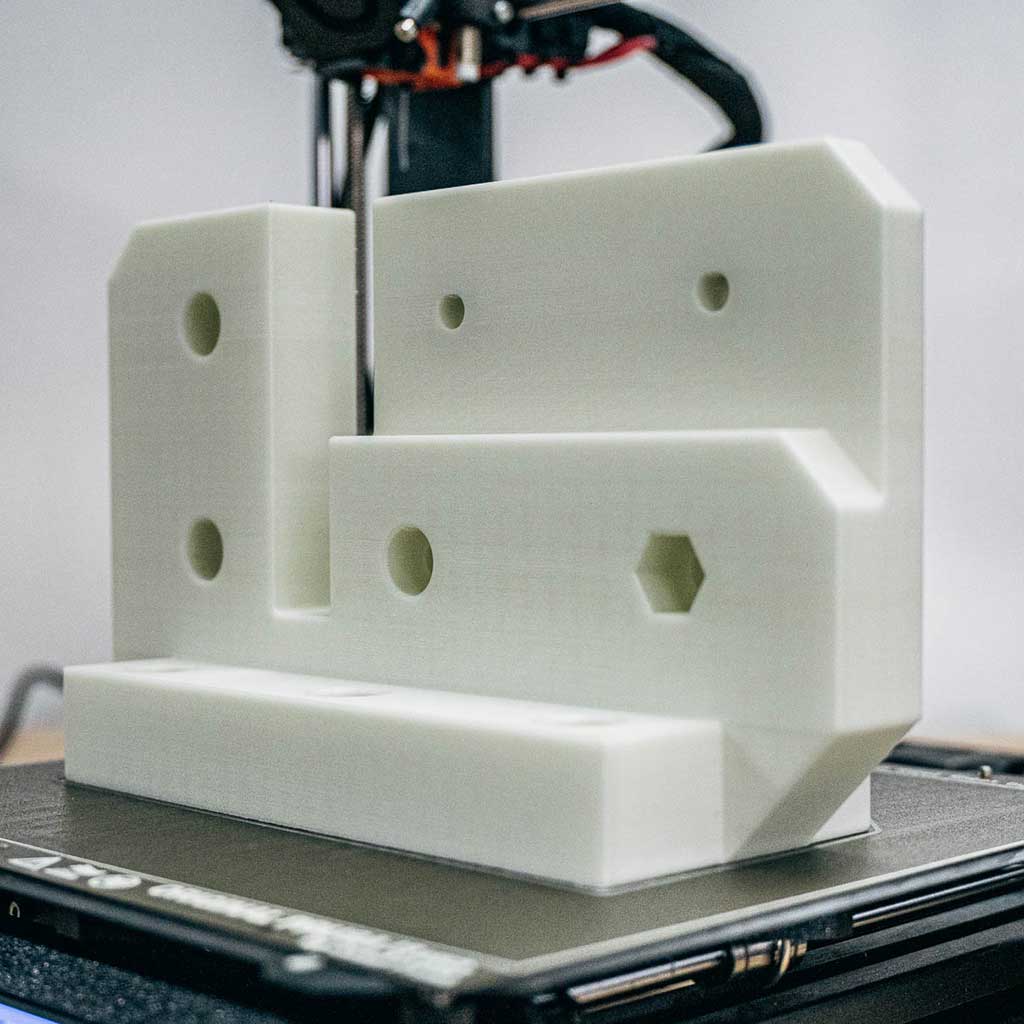

With Addigy® F1030 FR applications can be printed that require UL certification on flammability, such as enclosures for electric or lighting applications, connectors, and more. UL’s Blue Card program is specially developed for the certification of materials for additive manufacturing. Addigy® F1030 FR is completely halogen-free, making it environmentally friendly.

Key features

- First-ever UL Blue Card certified PA6/66 3D printer filament for open systems

- Validated in an UL-certified lab, the DSM material meets a UL 94 rating of V-0 at 1.6 & 3.2 mm wall thickness and a UL 94 V-2 rating at 0.85mm wall thickness.

- Environmentally friendly 3D printer filament that is halogen-free

- Easy to print

- Open platform solution

- A cost-effective alternative to other flame retardant materials

Applications

- Automotive connectors

- Electric and electronic connectors and enclosures

- Lighting enclosures

The UL94 V test performed on plastic materials measures flammability characteristics, examining how the material either extinguishes or spreads a flame once ignited.

Validated in a UL-certified lab, the DSM material achieved a UL 94 rating of V-0 at 1.6 & 3.2 mm wall thickness and a UL 94 V-2 rating at 0.85mm wall thickness. This means that the material, after ignition, extinguishes by itself in maximum 10 (V-0) and 30 (V-2) seconds. UL requires Blue Cards for 3D printing materials to be printer-specific; this material was tested on an Ultimaker S5 printer. Nevertheless, being an open platform material, users with any open platform fused filament fabrication system can work with Addigy® F1030 FR.

| Nozzle size: ≥ 0.4mm | Layer height: ≥ 0.1mm * | Flow rate: ± 100% |

| Print temp: ± 265 – 275° C * | Print speed: Average 50 mm/s * | Retraction: Depends |

| Heat bed: ± 110 – 115° C * | Fan speed: 0% | Printing surface: PA Adhesive |

| Enclosed printer needed: Yes | Heated Build Chamber: Preferred / Yes | Experience level: Intermediate |

*) Above displayed settings are meant as guidance to find your optimal print settings. These ranges in settings should work for most printers, but please do feel free to experiment outside these ranges if you think it is suitable for your printer. There are a lot of different type of printers, hot-ends and printer offsets that it is extremely difficult to give an overall one-size-fits-all setting.

*) First layer : 100 – 150% of first layer thickness.

*) Print speed: 50 mm/s (obeying the maximal throughput in cm3/s of the extruder). Print speed for “normal” nozzle size (0.4mm) and layer height (0.2mm), for other values print speed should be adjusted accordingly!

*) Do only remove printed object from print bed when print bed has cooled down to ambient temperatures, as otherwise printed part can deform severely.

*) Retraction dependent on printer type and filament diameter.

Filament length

| ρ: 1.25 g/cc | 50 gr coil | 0.5 Kg spool | |||

| Ø 1.75mm | ± 16.6m | ± 166m | |||

| Ø 2.85mm | ± 6.3m | ± 63m |

Storage and conditioning

Addigy® F1030 FR is supplied in airtight, moisture-proof packaging at a moisture level <0.05 w%.

In order to prevent moisture pick up and contamination, supplied packaging should be kept closed and undamaged. For the same reason, partially used bags should be sealed before re-storage. Allow the material that has been stored elsewhere to adapt to the temperature in the processing room while keeping the bag closed. To prevent moisture condensing on filaments, bring cold filaments up to ambient temperature in the print shop while keeping the packaging closed.

In case the filament has become wet, it should be dried. Using a hot air oven at 80°C for at least 4h is recommended. When storing the filament after printing, it is advised to seal the bag and add silica gel to the bag to keep the filament as dry as possible.

DSM Plastics Finder

For more technical information and guidelines please visit DSM Plastics Finder.

Product export information

| HS Code: 39169090 | Description: Monofilament | Country of origin: the Netherlands |

Compliance*

This filament is compliant to below listed directives and regulations.

- RoHS directive 2011/65/EC

- REACH directive 1907/2006/EC

*) This declaration of conformity to directives and regulations is prepared according to our present standard of knowledge and may be amended if new cognitions are available and applies only for the above-described products.

Safety Datasheet: