PEI ULTEM 9085

PEI ULTEM 1010

PEI filament

PEI filament stands for Polyether Imide and is one of the few high-quality 3D printing filaments. Whereas many filament materials focus mainly on how they make the print look in the end, there are a number of filaments that take performance to an even higher level. Due to their superior mechanical strength and thermal stability, these filaments are suitable for printing in industrial environments where more than just appearance matters. PEI 3D filament is one of these filaments. In this text we will tell you more about what the filament is capable of, what you can use it for and what the advantages and disadvantages of the product are.

What is PEI 3D printing filament?

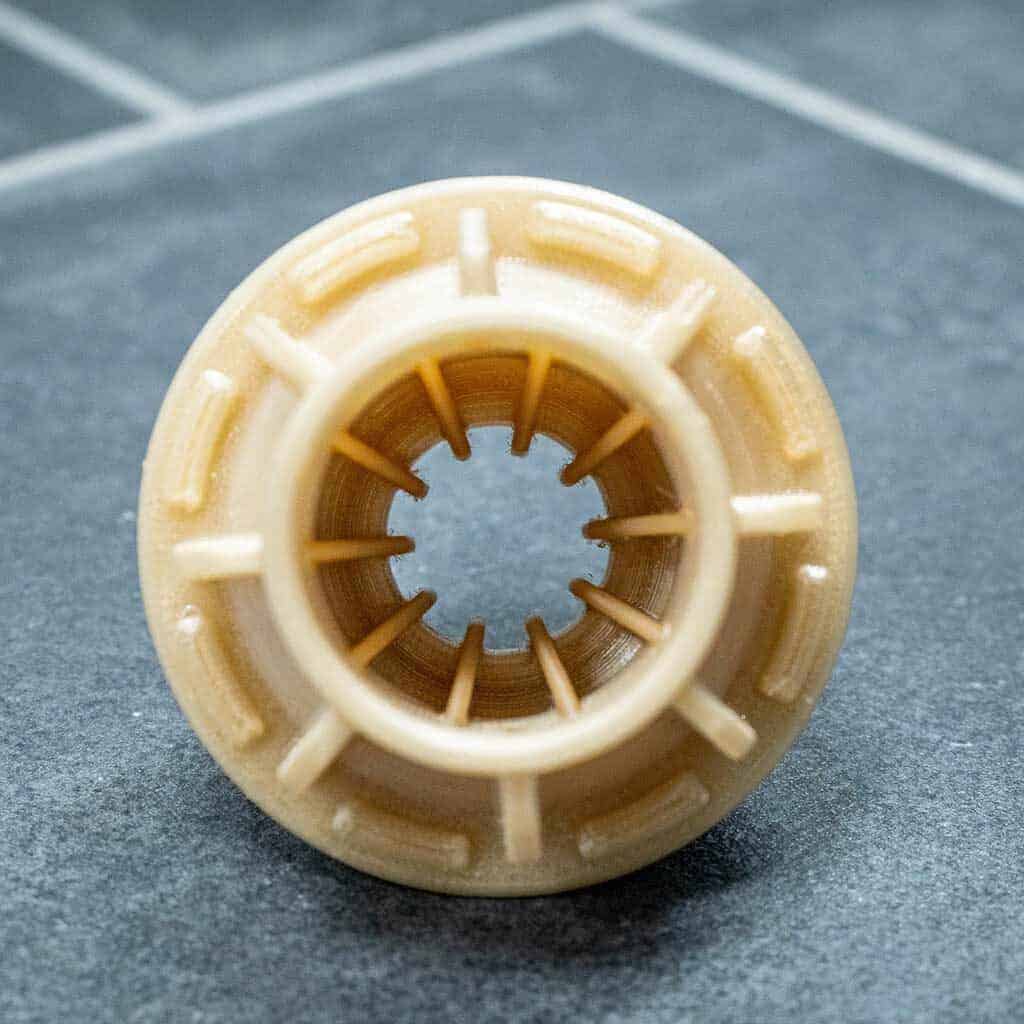

PEI filament was first developed by Joseph Wirth from the Plastic Division of GE in the early 1980s. The 3D printing filament has a characteristic semi-transparent amber colour. The reason why the filament has become known in 3D printers is that this plastic has a very high mechanical strength. Coupled with stable electronic properties and excellent chemical stability, it is a very strong filament.

PEI filament, part of the PAEK family

PEI is together with PEEK (Polyether ether ketone) a plastic that belongs to the chemical group PAEK (polyarylether ketone). This makes PEI filaments sought-after for their exceptionally strong mechanical strength and stability in high-temperature conditions. This type of filament is resistant to chemical attack and does not degrade when exposed to outdoor conditions.

Pro tip: PAEK filaments are a safe choice as they do not release toxic fumes when heated.

Advantages and disadvantages of PEI

PEI filament is a product that can be widely used in a large number of technical and industrial components. This is due to the fact that the product possesses high performance characteristics. Despite the fact that the filament has quite a few strong advantages, you must make sure that you use the filament for the right applications.

For example, PEI has a number of strong advantages, but it also has some debilitating setbacks when used in the wrong way.

Pro's:

Rigid and strong

As already described, PEI filament is mainly seen as an enormously strong product. For example, PEI has a tensile strength of 95MPa and a Young's modulus of 3.2 GPa.

Good thermal and chemical stability

In addition to its enormous strength, PEI filament also beats many competitors in the field of thermal and chemical stability. Other high temperature filaments, such as ABS filament and Nylon, are also normally considered to have these properties. However, in the field of stability this filament is by far the winner. PEI has a glass transition temperature of 217 °C and begins to melt at 240 °C. This makes the filament an excellent material for functional parts that have to endure a lot of friction.

The chemical stability of PEI also allows it to be used in versatile applications. For example, the filament is ideal for use when the parts are exposed to UV radiation.

Con's:

Higher price

Compared to other 3D printing filaments, the PEI 3D product is a bit on the expensive side. Where you already have a 1KG spool of PLA for €16,52, PEI filament is a bit more expensive, namely: €59,92. For this reason, we recommend this sort of filament mainly to experienced 3D printers who have been in the business for some time. The price ensures that it is difficult to experiment with the filament on a large scale.

Few variations of PEI filament available

PEI filament has few different shapes. As a result, the filament is not very flexible. In some situations PEI filament is just the specific filament you are looking for, but when it does not match the applications you want to use it for, then PEI is not a product that is often used.