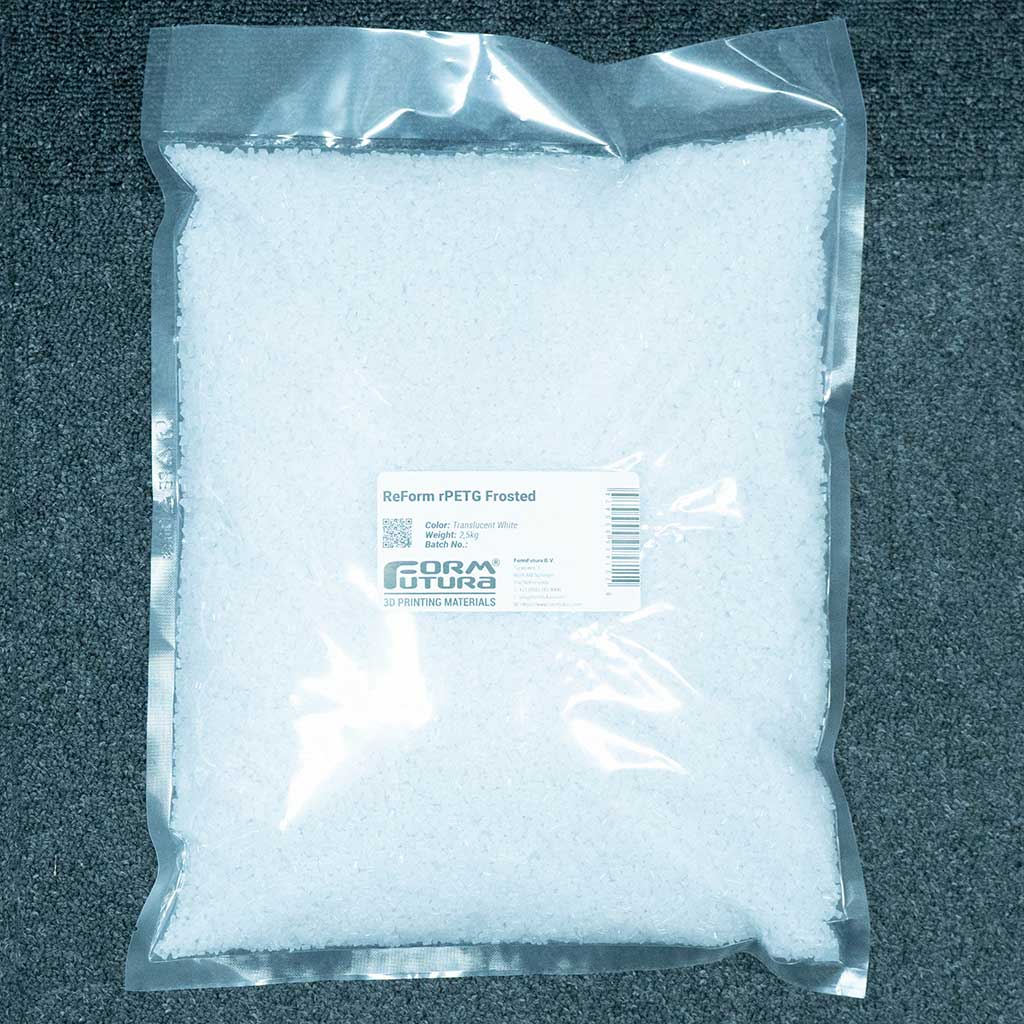

ReForm rPETG Frosted - Pellets

Recycled PETG for LFAM with excellent light diffusion.

Name :

[RPFR-PELTLWH-02500] ReForm rPETG Frosted - Pellets (2.5kg)SKU :

RPFR-PELTLWH-02500EAN :

8721496000474ReForm rPETG Frosted is a high-performance, translucent white recycled PETG granulate, engineered for Large-Format Additive Manufacturing (LFAM) applications. Its distinctive frosted finish provides excellent light diffusion. This makes it an ideal choice for lighting and visual applications where smooth, even illumination is essential.

Printed parts disperse light uniformly by minimizing visible light sources and eliminating harsh hot spots. The result is a soft, homogeneous glow that enhances both functional and aesthetic designs.

Ideal for Light-Diffusing Applications

Thanks to its balanced combination of durability, translucency, and visual consistency, ReForm rPETG Frosted is well suited for a wide range of applications, including:

- Lighting components and illuminated panels;

- Signage and wayfinding systems;

- Architectural and interior design elements;

- Office furniture and functional design objects;

- Exhibition stands and display systems.

Excellent Processability & Post-Processing

ReForm rPETG Frosted is designed for reliable performance in LFAM systems and offers strong mechanical properties and smooth printability. Finished parts can be easily drilled, sawn, screwed, or bonded with adhesives, allowing seamless integration into complex assemblies and final products.

Key features

of ReForm rPETG Frosted

- Uniform Light Diffusion – Translucent frosted white appearance ensures soft, even illumination.

- High Impact Strength & Crack Resistance – Delivers durability and reliability for large-format 3D printed parts.

- Easy Post-Processing – Compatible with common mechanical and adhesive finishing techniques.

- Good Chemical Resistance - Good resistance to cleaning agents, various chemicals, and environmental factors, extending the printed part’s lifetime and maintaining surface quality.

- European-Made Quality Compound – Manufactured in Europe using high-grade recycled PETG, ensuring consistent quality, reliability, and traceability throughout the production process.

Specifications

Material properties

MVR

260°C, 2.16kg)

Density

Mechanical properties

Tensile modulus

Flexural strength

Elongation at yield

Elongation at break

Charpy impact strength (23°C unnotched)

Charpy impact strength (23°C notched)

Thermal properties

HDT A

HDT B

Vicat softening temperature

Typical value

11-13 cm3/10min

1,27g/cm3

2220 MPa

70.6 MPa

5%

37%

No break

Ca. 7,4 KJ/m2

64°C

71°C

82 °C

Test Method

ISO 1133

ISO 1183-1

ISO 527

ISO 178

ISO 527

ISO 527

ISO 179

ISO 179

ISO 75

ISO 75

ISO 306

Processing ReForm rPETG Frosted

Drying: 6-10hrs at 65 °C (<400ppm / 0,04%) *

Do not exceed a drying temperature of 65 °C, as higher temperatures may cause pellet softening and caking within the drying hopper.

Zone 1: 210°C ±20°C

Max temp: 240°C

Zone 2: 220°C ±20 °C

Die temp: 240°C ±20 °C

Zone 3: 230°C ±20 °C

Storage and handling of ReForm rPETG Frosted

ReForm rPETG Frosted is an inert and safe material under standard storage conditions, presenting no significant hazards. To ensure maximum quality, stability, and long-term performance, proper storage practices are recommended.

For best results:

- Store in a tightly sealed container to protect against moisture absorption.

- Keep in a dry, cool, and well-ventilated environment.

- Avoid direct exposure to sunlight or intense artificial light to preserve material integrity.

By following these guidelines, ReForm rPETG Frosted will maintain its reliability and print performance over time.

Product export information

| HS Code: 39079980 | Description: PETG resin in primary form | Country of origin: European Union |