What is LFAM Printing?

Technical Specifications

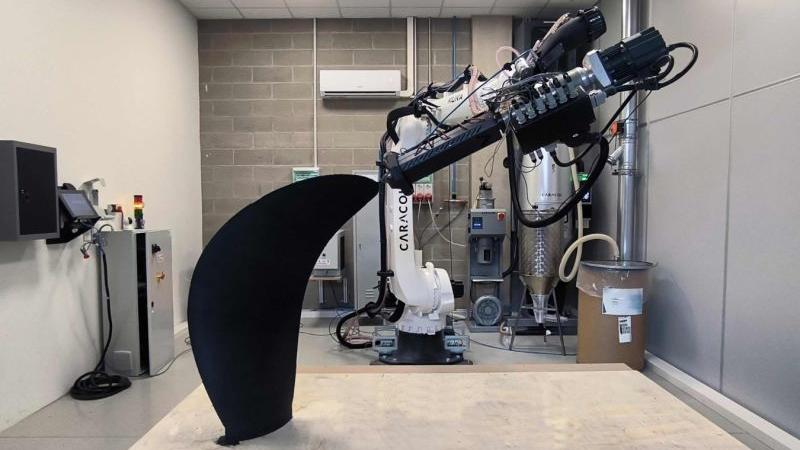

What is LFAM Technology?

Large Format Additive Manufacturing (LFAM) is a 3D printing process designed to produce oversized parts by extruding thermoplastic pellets at high speed. It enables rapid production of strong, lightweight components at a scale often measured in meters rather than millimeters. LFAM is ideal for tooling, molds, prototypes, and end-use parts in industries such as aerospace, automotive, and marine.

Explore Our LFAM 3D Printing Services

Our LFAM technology delivers large, durable parts quickly and cost-effectively. Perfect for oversized prototypes, tooling, and production components, we combine speed and strength to meet your biggest manufacturing challenges with expert support throughout the process.

Specifications

Build Volume:

Layer Height:

Supported Materials:

Colors Available:

Lead Time:

Details

Up to 2000 × 2000 × 2000 mm

0.5 mm – 10 mm

FormFutura Material, others on request

Wide range available; custom colors on request

From 7–14 working days, depending on quantity and size

Specifications

Build Volume: Up to 2000 × 2000 × 2000 mm

Layer Height: 0.5 mm – 10 mm

Supported Materials: FormFutura Material, others on request

Colors Available: Wide range available; custom colors on request

Lead Time: From 7–14 working days, depending on quantity and size

Efficient, Flexible Large-Part Production

Flexible Large-Scale Manufacturing

Our robot-guided pellet extrusion allows for complex shapes, including sweeping curves, undercuts, and internal channels—design features not possible with traditional large-format techniques.

Fast Production with Cost Efficiency

With high-speed extrusion and minimal material waste, we deliver large-scale parts quickly and at a fraction of the cost compared to CNC machining or composite lay-up.

Pellets for Performance and Sustainability

Select from a diverse range of high-quality pellets, including virgin, reinforced, and recycled options such as PP, PETG, ABS, PA, and many others. Our materials are carefully chosen to help you strike the perfect balance between mechanical performance, lightweight design, and environmental sustainability. Whether your project demands strength, durability, or eco-friendly solutions, we provide the ideal pellet to meet your specific needs and support your goals.

Example Prints