We recently launched our ApolloX Foaming, a filament that combines the excellent UV and weather resistance of our ApolloX ASA (Acrylonitrile Styrene Acrylate) with advanced active foaming technology.

Why add advanced foaming technology?

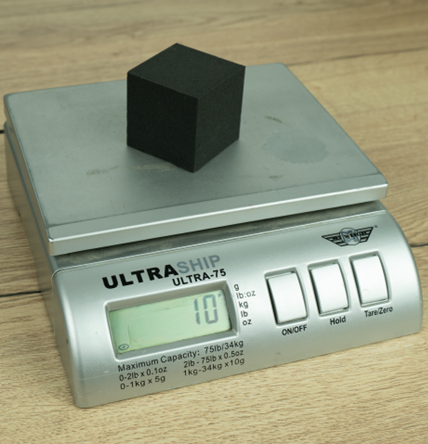

ApolloX, our tried and tested modified ASA, is a very versatile filament in itself, so why would we add foaming technology to the mix? To offer a true enhancement in terms of end object weight, amongst many other advantages, of course. Keep reading to find out more!

How does this technology work, you ask? The foaming process activates at around 230°C, with the maximum effect achieved in the range of 270°C–285°C. When printed below 230°C, the material behaves like standard ASA, giving users great flexibility in tuning print settings. When fully foamed, ApolloX Foaming expands up to three times its original volume, reaching an exceptionally low density and offering precise control over material flow, allowing you to reduce material usage by up to 66%.

Key features of ApolloX Foaming ASA

- Over 3x weight reduction of printed parts - Greatly reducing the final density.

- Active foaming technology - Activated at 230–285°C.

- Adjustable material density - Full control over flow and part structure of your prints.

- Over 3x more yield – One spool of ApolloX Foaming can print as much as three spools of standard ASA.

- UV and weather resistant – Ideal for outdoor applications as it won’t degrade under sunlight or extreme weather conditions.

- Matte finish - Aesthetically pleasing end results by hiding the layer lines.

Applications of ApolloX Foaming ASA

- Aerospace and automotive parts - Ideal for exterior parts that require a lightweight, sturdy solution.

- Drones & RC modeling - The perfect option for modeling remote controlled objects like drones that require withstanding impact and environmental stress.

- Lightweight functional components - The ideal choice for components requiring lightweight and mechanical specs.

- Manufacturing end-use products - Ready for end-use manufacturing of a wide range of products. The possibilities are endless. The ceiling is your own creativity.

How to 3D Print with ApolloX Foaming ASA

To achieve the best results when printing with ApolloX Foaming, it’s essential to follow the recommended print settings and preparation techniques.

General printing guidelines

| Parameter | Recommended Value |

|---|---|

| Nozzle Temp. | ± 220 – 285° C |

| Bed Temp. | ± 60 – 90° C |

| Print Speed | 30 – 60 mm/s |

| Cooling Fan speed | 0 - 50% |

| Enclosure | Yes, 40° C |

Tips for Optimal Printing

- Use an enclosure – Helps maintain a stable temperature and reduces warping.

- Bed adhesion techniques – A heated bed with PEI sheets, ABS juice, or Kapton tape ensures strong first-layer adhesion.

- Reduce cooling – Too much cooling can lead to weaker layer adhesion; keep the fan off or at low speeds.

- Proper ventilation – Like ABS, ASA emits fumes, so ensure a well-ventilated workspace.

- Experimentation – we encourage you to play with the temperature and tune the extrusion width to achieve the desired material density and provide precise control over the material flow.

Final thoughts

If you need a durable, UV-resistant, lightweight and precise filament for your next 3D printing project, ApolloX Foaming is the perfect candidate. With its excellent mechanical properties, variable material density, lightweight nature and relative ease of use, It's bound to be your new favorite filament for fun and professional projects alike.

Interested in trying this innovative filament?